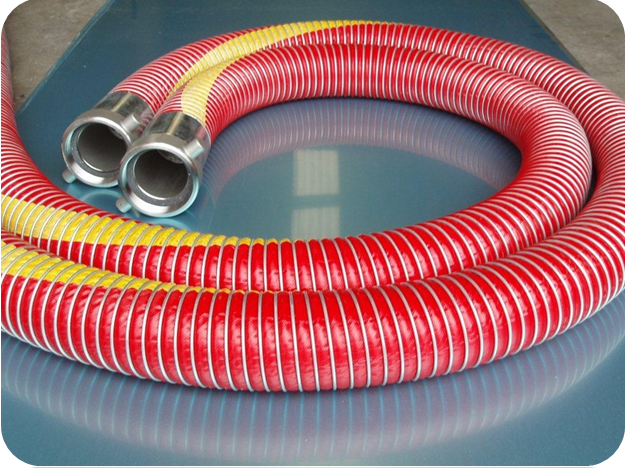

Composite Hose

Lantech composite hose construction is unique consisting of many spirally wrapped plies of thermoplastic fabrics and films held together by internal and external wire helices.

The fabrics and outer wire provide most of the longitudinal and radial strength of the hose and the films prevent the contents from escaping.

This type of hose is not vulcanised or bonded like rubber hose, the integrity of the hose is maintained by the tension of the interlocking inner and outer wire helices.

Polypropylene lined composites come with a polypropylene coated inner wire and a galvanised outer.

PTFE lined composites are supplied with a Stainless steel inner and galvanised outer wire as standard but we can supply different configurations for special applications.

This method of construction makes the wall of the hose highly corrugated. This imparts a high degree of flexibility, but also allows elongation under pressure to be quite high compared to most rubber hoses.

Composite hoses, compared to rubber hoses intended for similar applications, are generally much lighter and more flexible. This is the main advantage of a composite hose, particularly where the hose is to be handled frequently e.g. road tanker, ship to shore and in Plant service.

Applications

Can be used for road tanker loading and off-loading in plant applications where a robust flexible hose is required with a proven safety record.

Composite hoses are designed for suction and discharge of a wide range of chemicals and acids, alkalis and much more.

Properties

- Size range: 1” NB up to 12” NB

- Working Temperatures: -40 C up to 115 C (dependent on type )

- Working pressure: Full vac up to 10 Bar

- Lengths up to 20 meters

- Easy to handle due to hose flexibility

- Lightweight

- Antistatic and electrically conductive.