Description

|

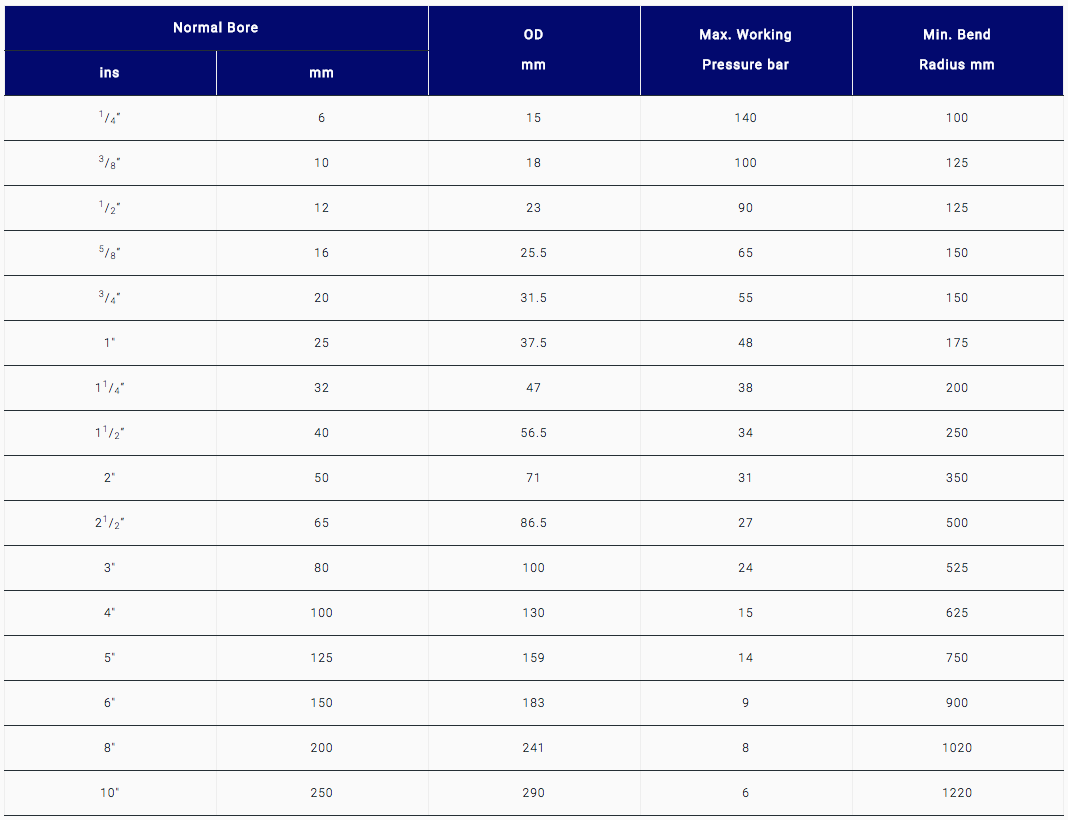

Normal Bore

|

OD

mm |

Max. Working

Pressure bar |

Min. Bend

Radius mm |

|

|

ins

|

mm

|

|||

|

1/4“

|

6

|

15

|

140

|

100

|

|

3/8“

|

10

|

18

|

100

|

125

|

|

1/2“

|

12

|

23

|

90

|

125

|

|

5/8“

|

16

|

25.5

|

65

|

150

|

|

3/4“

|

20

|

31.5

|

55

|

150

|

|

1″

|

25

|

37.5

|

48

|

175

|

|

11/4“

|

32

|

47

|

38

|

200

|

|

11/2“

|

40

|

56.5

|

34

|

250

|

|

2″

|

50

|

71

|

31

|

350

|

|

21/2“

|

65

|

86.5

|

27

|

500

|

|

3″

|

80

|

100

|

24

|

525

|

|

4″

|

100

|

130

|

15

|

625

|

|

5″

|

125

|

159

|

14

|

750

|

|

6″

|

150

|

183

|

9

|

900

|

|

8″

|

200

|

241

|

8

|

1020

|

|

10″

|

250

|

290

|

6

|

1220

|